Manufacturing Equipment & Advanced Technology for Precision and Efficiency

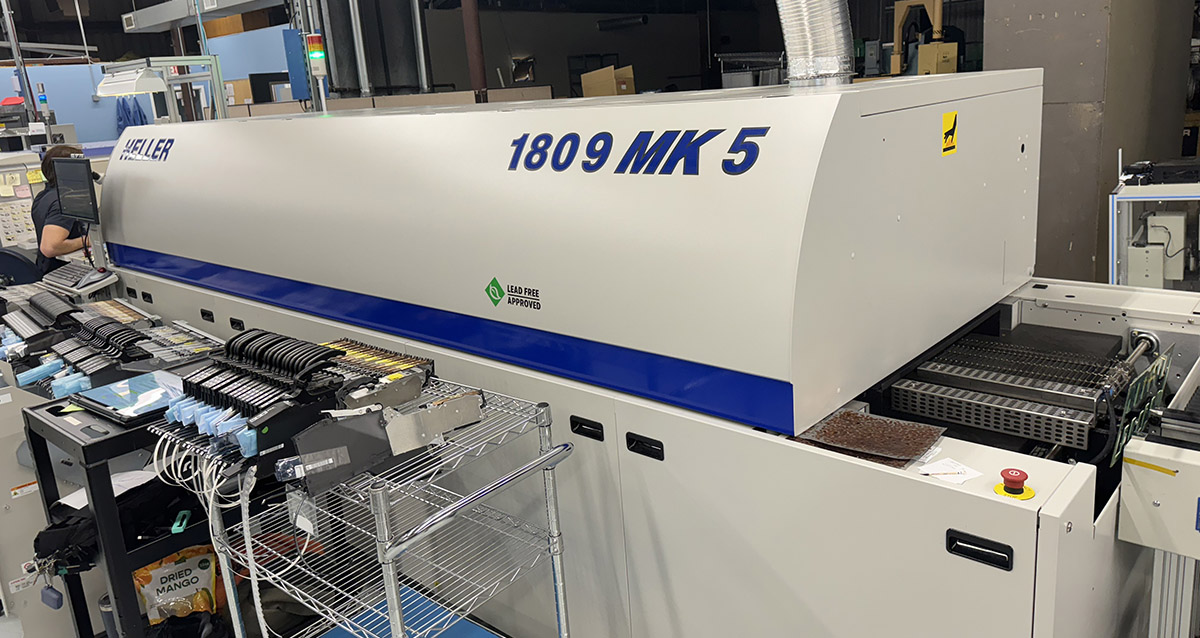

At Adonai Technologies, our 10,000 sq/ft facility is equipped with advanced technology for precise PCB assembly. We handle projects of all sizes, from rapid prototypes to large production runs. Our equipment includes the MPM Momentum II 100 paste printer for accurate paste application, the Yamaha I-PULSE M20 Surface Mounter for versatile SMT assembly, and the Heller 1809 MK5 Reflow Oven for consistent soldering.

We also use the ERSA VERSAFLOW 3/35 for selective soldering and Dage X-ray for detailed internal inspections. Quality control is key, with automated optical inspection (AOI) and de-ionized water cleaning protecting each assembly. With cutting-edge equipment and skilled technicians, we ensure reliable, high-quality results for every project.

Adonai Manufacturing Equipment

Cleaning & Protection

Cleaning and protective equipment ensures component cleanliness and durability for PCB assemblies in demanding environments.

Inspection Equipment

Advanced inspection equipment offers non-destructive X-ray and automated optical inspection, ensuring defect-free, reliable PCB assemblies.

Soldering Equipment

Adonai soldering equipment provides precise selective and high-volume wave soldering, delivering reliable connections for all PCB assemblies.

Reflow Ovens

Reflow ovens ensure uniform soldering with precise thermal control, supporting high-mix and high-volume production for PCB assemblies.

SMT Equipment

High-speed SMT equipment for precision placement and high-volume capabilities. We deliver quality, efficiency, and dependable results.

Paste Printing

Precision paste printing equipment with consistent application and reliable quality control. We ensure accuracy, efficiency, and superior solder connections..