Conformal Coatings Ensure DurabLe & Reliable Electronics

At Adonai Technologies, our Conformal Coatings service provides a protective layer for electronics assemblies, safeguarding them from moisture, dust, chemicals, and other environmental factors

Essential for industries like aerospace, medical, and industrial electronics, our conformal coatings ensure that sensitive components continue to perform reliably, even in challenging conditions.

We offer a range of coating materials to meet specific durability and functional needs, each applied with precision to maintain product quality and longevity.

Conformal Coatings Capability

Moisture and Dust Protection

Our conformal coatings protect electronic assemblies from moisture and dust, which can compromise performance and longevity. These coatings create a sealed barrier, preventing contaminants from affecting sensitive components and ensuring consistent performance.

Key Benefits:

- Shields electronics from humidity, dust, and airborne contaminants.

- Enhances reliability in harsh or variable environments.

- Ideal for outdoor, industrial, and high-durability applications..

Acrylic, Silicone, and Urethane Conformal Coatings

We offer multiple coating types—Acrylic, Silicone, and Urethane—each selected based on specific project requirements. From high flexibility to chemical resistance, these coatings provide targeted protection for various environmental conditions.

Key Benefits:

- Acrylic coatings for fast-drying, general-purpose protection.

- Silicone coatings for extreme temperature resistance and flexibility.

- Urethane coatings for excellent chemical and abrasion resistance.

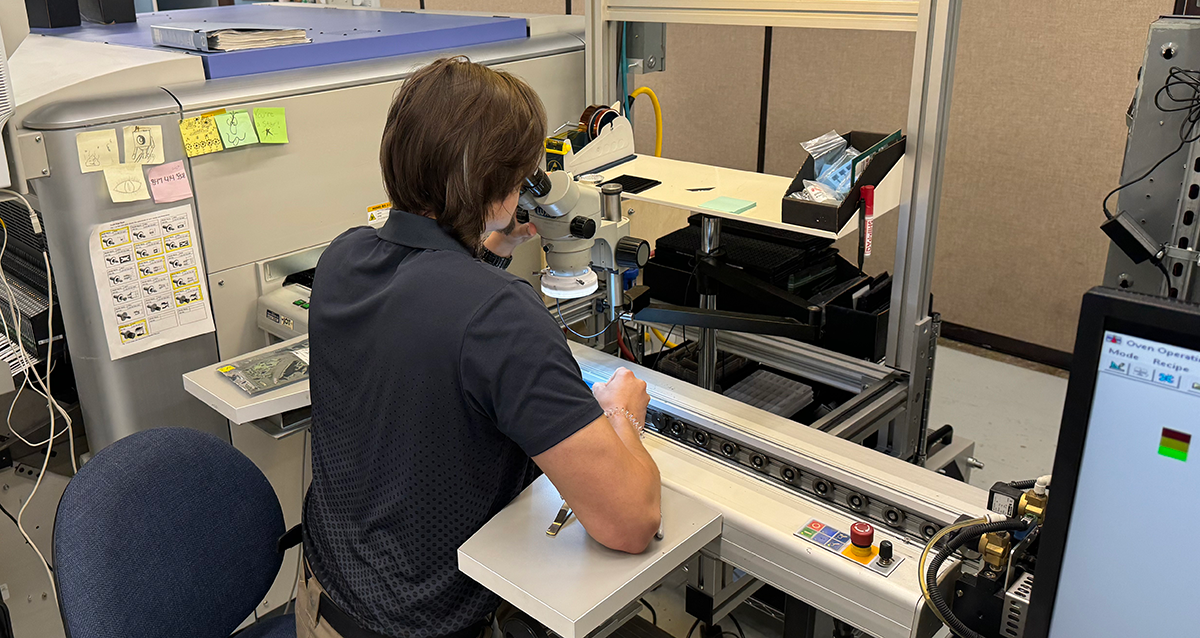

Application Precision

Our technicians apply conformal coatings with precision, ensuring complete and even coverage without adding unnecessary bulk. This precise application ensures that coatings protect critical components while maintaining performance and appearance.

Key Benefits:

- Ensures even coverage for consistent protection.

- Maintains board integrity without adding excessive weight or thickness.

- Ideal for complex geometries and sensitive components.

Inspection and Quality Assurance

Every coated assembly undergoes thorough inspection and quality assurance to confirm coating integrity and adherence. Using Automated Optical Inspection (AOI) and specialized tests, we ensure that each conformal coating is applied correctly and effectively protects the assembly.

Key Benefits:

- AOI and visual inspections for defect-free coatings.

- Verifies consistent application and adherence to all surfaces.

- Prevents premature failures due to coating inconsistencies.